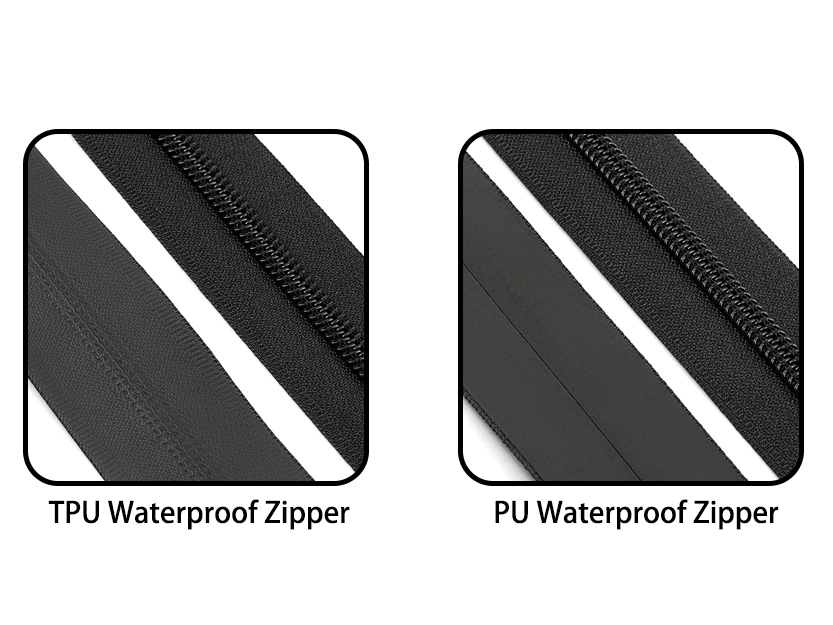

When selecting waterproof zippers for outdoor gear, it’s crucial to consider the coating used to ensure water resistance and durability in harsh environments. TPU (Thermoplastic Polyurethane) and PU (Polyurethane) are two common coating options applied to zipper tapes, often on nylon or plastic zippers, to enhance waterproof capabilities. Let’s explore the differences between TPU and PU coatings and how they impact zipper performance.

1. TPU-Coated Waterproof Zippers

- Material: TPU is applied as a coating to zipper tapes, usually on nylon zippers, providing a water-repellent layer.

- Features: TPU offers excellent water resistance, flexibility, and breathability. It is known for its smooth texture, and the surface can be customized with printed logos or patterns. Additionally, TPU-coated zippers maintain their durability in various conditions, including high humidity and moderate temperatures.

- Applications: TPU-coated zippers are ideal for outdoor clothing like raincoats, tents, and waterproof backpacks. The coating enhances the durability of nylon zippers, making them perfect for lightweight outdoor gear where flexibility and water resistance are key.

2. PU-Coated Waterproof Zippers

- Material: PU, another popular coating, is applied to the surface of nylon or plastic zippers.

- Features: PU coatings provide a double-layer waterproof membrane that offers superior resistance to extreme temperatures (from -10°C to 200°C). This coating also adds a leather-like appearance, making it popular for fashionable gear. PU coatings are known for their high durability, toughness, and wear resistance, ideal for heavy-duty outdoor use.

- Applications: PU-coated zippers are commonly used in luggage, extreme-weather gear, and heavy-duty outdoor clothing, where high performance in extreme conditions is required. The added toughness makes them suitable for long-term exposure to the elements, including intense heat, cold, and abrasion.

Why Nylon Zippers with TPU/PU Coatings?

Although TPU and PU coatings significantly improve the water resistance of zippers, the underlying material—usually nylon or plastic—is equally important for overall performance:

- Nylon Zippers: Lightweight and flexible, nylon zippers coated with TPU or PU are perfect for outdoor gear where mobility and flexibility are essential. Nylon’s durability, combined with waterproof coatings, ensures the zipper performs well in damp and rugged environments.

- Plastic Zippers: These are more rigid than nylon but are often used for applications where strength and resistance to environmental wear are critical. The TPU or PU coating adds the necessary water resistance without compromising the strength of the zipper.

Customization and Aesthetic Options

One of the benefits of TPU and PU coatings is their ability to be customized. Printed logos, patterns, and color matching are often added to these coated zippers, making them an excellent option for brands looking to integrate functional yet stylish zippers into their outdoor gear.